Cloud ERP for Food Manufacturing: How to replace legacy limitations

5 minutes reading

Food and beverage manufacturers are under pressure. Global instability, inflation, climate regulations, talent shortages, and shifting consumer habits have created a level of complexity the industry hasn’t seen in decades.

At the same time, advances in food technology like vertical farming, AI-optimized production, precision fermentation, and smarter supply chains are creating powerful new opportunities. But capturing those opportunities requires agility. And for many companies, the systems running their business aren’t built for it.

Legacy ERP platforms that once offered stability are now limiting innovation. The way forward? A rethinking of ERP itself, not as a cost center, but as a foundation for adaptability.

The pressure facing food and beverage manufacturers

Today’s food industry faces five converging challenges:

- Inflation and margin erosion have made cost control and spend visibility business-critical.

- Sustainability expectations from consumers and regulators are raising the bar for transparency and traceability.

- Labor shortages are driving automation, but adoption remains uneven.

Technology adoption is increasing, but so is the gap between digital leaders and laggards. - Supply chain volatility is demanding shorter reaction times and more flexible infrastructure.

These aren’t one-off disruptions. They are the new normal.

Why traditional ERP can't support modern food operations

Many manufacturers rely on traditional ERP systems that are heavily customized, slow to update, and expensive to maintain. Over time, they’ve become brittle. Innovation slows down because upgrades are too painful. Business users turn to spreadsheets. IT teams spend more time maintaining infrastructure than enabling transformation.

Upgrades often take years, drain budgets, and end in compromise. New capabilities are delayed. Integrations break. The ambition at kickoff rarely survives to go-live. And once a project is finally done, most companies return to "keep the lights on" mode, with innovation postponed until the next cycle.

The result is a widening gap between what the market demands and what the systems can deliver.

Rethinking ERP with cloud-native, industry-specific platforms

A new generation of ERP platforms is emerging, designed specifically for manufacturers. What sets them apart isn’t just the cloud. It’s the combination of industry-specific capabilities, preconfigured processes, and a cloud-native architecture that enables continuous delivery of improvements.

This means:

- No waiting years for new features

- Software that fits the way your business actually operates

- A platform that evolves continuously, without downtime or disruption

These systems aren’t built for IT. They’re built for operations leaders, finance teams, and decision-makers.

What manufacturers gain with modern ERP systems

Manufacturers adopting modern ERP platforms are seeing real results:

- Faster access to real-time operational data

- Better handling of product recalls and traceability requirements

- Forecasting that adjusts for weather, shelf life, and promotions

- Lower IT burden through built-in automation and integration

- The ability to innovate incrementally instead of in massive, costly cycles

These businesses avoid the stop-start pattern of traditional ERP. Their systems become a strategic enabler, not a barrier to change.

How to choose the right cloud ERP for food manufacturing

For food and beverage manufacturers, the right ERP system should deliver:

- Industry fit

Does the system reflect your real-world operations, including batch tracking, compliance, and planning? - Adaptability

Can the platform evolve with you? Can you adopt new capabilities quickly without disruptive upgrades? - Pace to value

Does the solution come with preconfigured content and clear implementation paths to accelerate deployment?

If the answer to any of these is no, it may not be designed for your needs.

Before migrating to the cloud, start with an ERP readiness assessment

Many companies hesitate to make ERP changes because of perceived risk. That’s fair. But modern platforms offer a more incremental approach that begins not with implementation, but with clarity.

A cloud readiness assessment helps you understand your current position. It provides a secure, low-impact scan of your existing environment, integrations, and configurations. The output is a roadmap: business impact, migration path, and cost projections based on your actual system, not assumptions.

Rethinking ERP is a business decision, not just an IT one

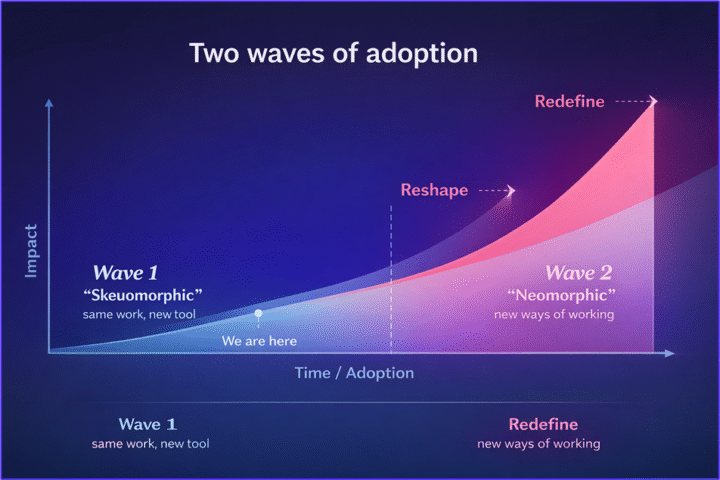

The world is changing fast. Long upgrade cycles and legacy tools can’t keep up. Modern ERP isn’t just about digitizing processes. It’s about making better decisions, responding faster, and enabling teams to focus on what moves the business forward.

For food and beverage manufacturers looking to compete, it’s not just about replacing a system. It’s about replacing the limitations that came with it.

Want to learn more about what a modern ERP looks like?

Read more about our offering around Infor M3 CloudSuite here.

Related news

Why AI adoption in organisations often gets stuck between tools and vision

When transport planning becomes a bottleneck in production